Around 3.8 million people work in metal & electrical companies and manufacture a wide variety of products: from vending machines to gearwheels. Many workplaces are located near ovens, hot machines and in halls that are not air-conditioned. The heat load of foundry workers or welders is sometimes up to 50°C and more. This affects the cardiovascular system and health. Concentration and performance are affected – exhaustion syndromes compromise not only the daily work routine but also the after-work and private life.

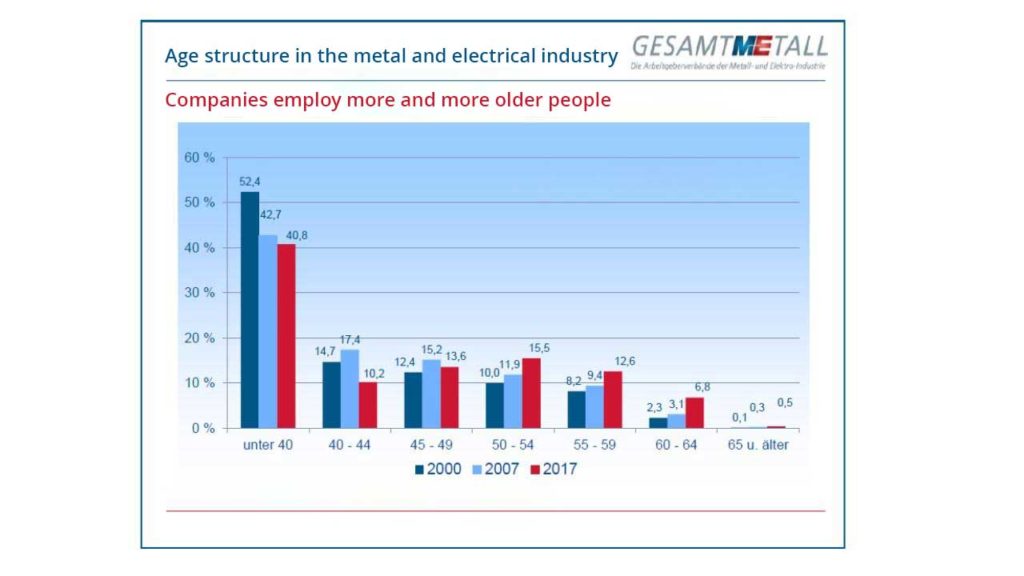

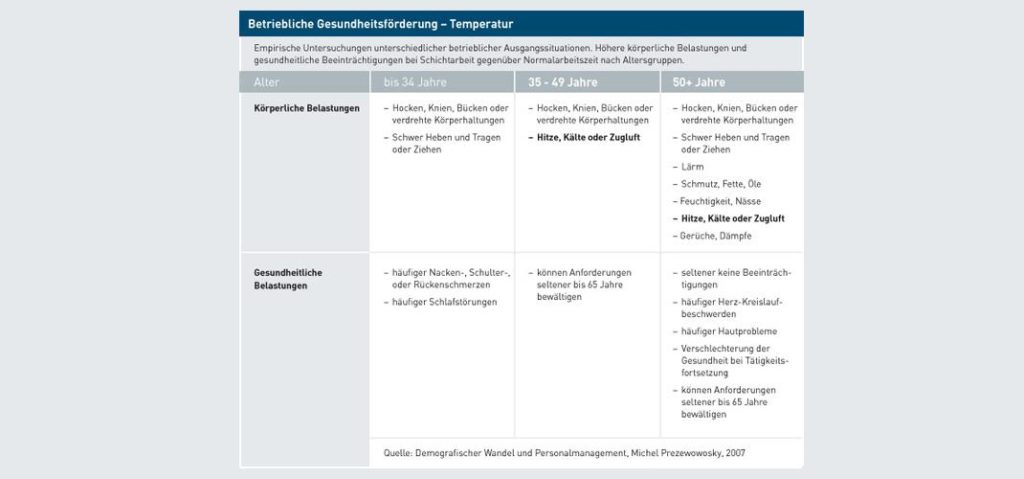

HEAT IS PARTICULARLY HARD ON OLDER EMPLOYEES

The percentage of older employees is increasing year by year. For this reason, preventive health care is particularly important in hot weather. Cardiovascular diseases are still the most common cause of death in Germany.

Already from the age of 35, the topic of climate and heat is becoming increasingly important. However, even many younger people also complain about heat-related health issues. According to workplace guidelines, measures such as cooling vests must be used from as low as 26°C and no later than 32°C. From 37°C the workplace is a hot workplace.

EFFECTIVE HEALTH PREVENTION IN HEAT IS ESSENTIAL

In order to protect the health of employees in the metal and electrical industry, preserve their productivity and also ensure an active after-work life, an effective heat protection strategy was developed with climate-neutral E.COOLINE cooling functional clothing.

TESTED IN THE STEEL MILL

Especially in the steel mill, working conditions are often extreme. In a wide-ranging test, the E.COOLINE cooling functional clothing in the form of vests, bandanas, etc. was tested over a longer period of time with great success.

It has been shown, with IR heat images as well as in the form of heart rate measurements, that the use of E.COOLINE significantly reduces heat stress. The staff’s recommendation was clear: E.COOLINE. Here you can find the 18-page test report

E.COOLINE IN THE HARDNESS TEST WITH LIQUID ALUMINIUM

Employees in the metal sector are creative. In order to convince themselves of the quality of the E.COOLINE products, they took part in a live test in front of a running camera. An activated E.COOLINE SX3 vest was hanged on site and directly doused with liquid aluminium. The liquid metal beaded off, the cooling vest passed the test and had no damage to the inside. Really cool!

Here is the impressive video…

E.COOLINE IN THE ON-SITE TEST

E.COOLINE – the air conditioner to wear – is new and innovative. Especially in fields such as in a foundry, in engine production, but also in welding or in assembly and maintenance. Surprisingly, the effects are not limited to a better body temperature.

E.COOLINE also ensures “cooler” interaction with each other through less heat stress and thus improves the working climate – but you read for yourself: